Getting a fitting transformer bobbin for ferrites is not easy under normal circumstances, but even more so for cores of unknown type. Usually, the dimensions follow a somewhat standardized pattern, but then your application might demand for separate winding chambers or mounting aids which are simply not available to the standard customer. So why not 3D print it?

The motivation is to use an old ferrite core for a high voltage lab supply. It will be driven far below its theoretical maximum spec as I only know it came from a ~50W power supply. My design (a flyback converter) requires a single winding in single-ended mode for the primary consisting of 23 turns, and a secondary of 235 turns capable of withstanding roughly 1kV. For winding I use standard enameled solid copper wire of unknown brand, which will probably not survive the full voltage. As a solution, I want to separate the secondary into 6 compartments of 40 turns each to reduce the maximum possible voltage between two neighboring wires to a maximum of 166V, which is well below the breakdown range. Without compartments, the left-to-right-to-left layer winding – which will occur somewhat naturally – may cause turns with extreme voltage difference to end up touching, leading to arcing sooner or later. To additionally strengthen the winding, a soaking resin could be applied.

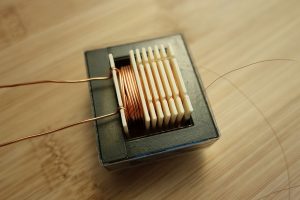

Using the dimensions of the core as a base, some modeling in Tinkercad yielded this: