Alright, so I finally decided what I want to do as kind of a long-term project in the coming time: A CNC mill which will get heavy use in the fabrication of PCBs, faceplates and enclosures. My case-building skills plain suck, so this nifty device will be helping me in the future. Also, this is my first real all-out mechanical build – meaning no straight way to the goal. In the end, it will probably have become a lot more expensive than I currently still hope for, but we’ll see about that ;-). (Account the extra expenses to learning and refilling the scrap parts box, distracts the wallet from groaning somewhere in a dark corner. Works most of the time.)

As I already wrote above, the main tasks for the machine will be PCB milling and drilling, machining wood, acrylic, plastics and aluminum. Maybe copper, and in the far future I want to take a shot at some steel sheeting, but all that is off the radar right now. I will try to aim for high precision and adequate stability. A portal mill seemed like a good idea at the time, especially because a moving table makes the machine just so much bigger while the workpiece must stay within relatively modest dimensions. I played with the thought for a while but then dropped it in favor of this design.

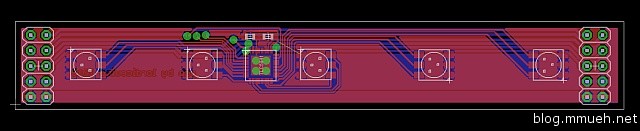

The whole thing will be controlled by linux-EMC or Mach3, maybe I can even fit a small EPIA-800 mainboard as a control computer in there if the drive mechanism allows enough leftover space. The controller will be custom made, mainly for education purposes on my side.

First, I did a draft in SketchUp to get a feel for the problems and dimensions, though it is already outdated by now. I will update it in the next days when I need exact measurements of the whole device again. Right now pen, paper and calipers are sufficient. The materials are almost all bought at the local hardware store, MDF sheets, V2A screws and aluminum parts in standard sizes. Fortunately they do have a decent free cutting service whose operators hit the measures on the tenth of a millimetre (or up until now, at least). Saves me some of the work.

Construction began with the machine table, which is a solid piece of 22mm thick MDF wood, 500 x 600 mm in dimension (long side along rails). The sheet will be reinforced with aluminum from below so it doesn’t bend or skew, but first the drive mechanics and electronics compartment below the table need to be done. Just as a side note, the milling area will be somewhere around 450 x 450 mm but that number is not final. I have noticed that some more changes to table and X-axis construction might be necessary and those will of course change the useable space on the table.

Machine table:

The table is carried by two 67 x 35 x 2.5 mm aluminum rectangular tubing. The tubing also supports the linear rails which are self-constructed and still need to prove their usefulness. The first rail is already installed (see pictures), the running sleds are in preparation (still need some standoffs) and the portal flanks are halfway done.

Linear bearings:

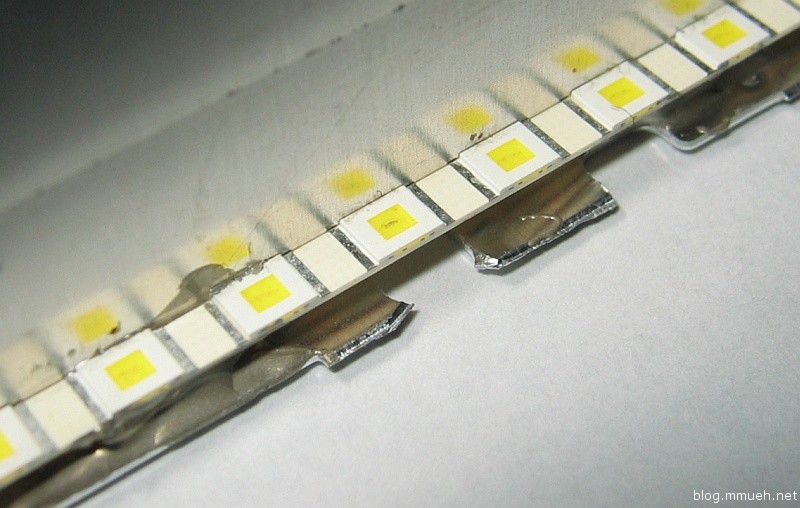

Made from 15.5 x 15.5 x 1.5 mm aluminum tubing with a slight groove in the exact center of each side, running along the length. The other part is a C-rail that fits exactly into this groove and supports the tubing nicely, giving it an exact 45° angle but believe me is a HELL to drill, even with a drill press. The carriage sleds of the portal consist of another 45°-rotated piece of the same tubing with ball bearings mounted to its sides in a way that they stand at 45° angles on the surfaces near the upper and lower edge of the rail. I have no picture of this part, will get some later today after I get around to reassembling the carriages.

The second rail is still in the making, will probably be finished today or tomorrow. I’ll try to get more pictures of the process but holding a camera while drilling seems not all that fun.

A small teaser:

The stepping motors I got for quite a bargain, pretty powerful with around 1.85Nm holding torque. These beauties weigh in at 1.4 kg per piece, measure about 100 x 56 x 56 mm, sport a 6mm diameter shaft and survived the whole shipping torture without stuffing material or bubble wrap (YES seriously, who in his right mind ships 5 x 1.4 kg worth of steel and copper unwrapped in some otherwise empty cardboard box?!?) without even a slight dent in the shafts. The faceplate got a bit banged though, but nothing that can’t be polished up.

The drivers for these will be of my own making, probably AVR-controlled MOSFET fullbridge circuits. Half-stepping is planned, but I have not yet decided on microstepping. I guess that will be added if necessary for precision.

So long, stand by for more :-)

EDIT: Just noticed that this wordpress blog seems to distort my pictures if they open in the lightbox. Will see if I can fix that, must be something wrong with the script.

EDIT: Fixed, seems like some unwanted css found its way into the template.